Will Your Glue Joints Hold?

Most woodworkers struggle with trusting their glue joints. Will they hold up? How much stress will they handle?

I used to struggle with the same insecurities about my glue joints when I started woodworking. How did I get over it? By continually doing quality control checks on my glue joints through destructive testing.

QC Through Destructive Testing

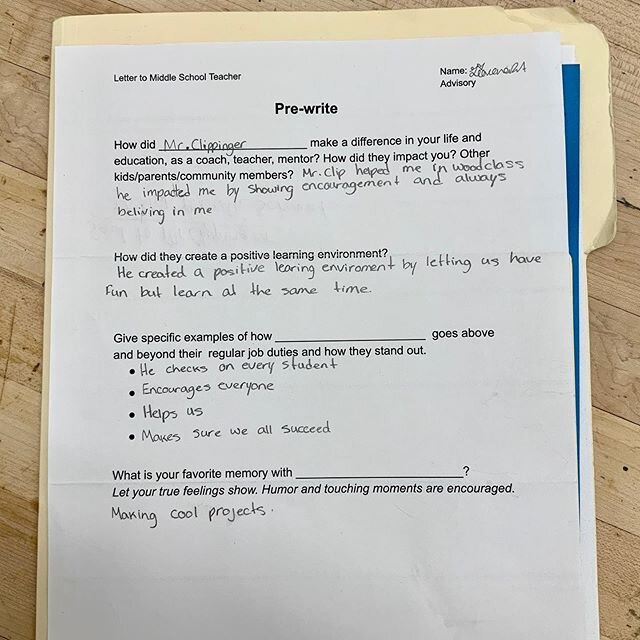

Ash glue joint.It is important to know that I don't do things one time in my shop just so I can share it with my friends online, the techniques and principles that I share are the things that I practice everyday in my shop. Testing my glue joints is something that I do in most every project.

Ash glue joint.It is important to know that I don't do things one time in my shop just so I can share it with my friends online, the techniques and principles that I share are the things that I practice everyday in my shop. Testing my glue joints is something that I do in most every project. Cherry glue joint

Cherry glue joint

When I glue up panels, thick or thin, I always glue them a little oversize and then cut them down to the finished width and length. I like to use the end drop pieces of a glued up panel for destructive testing to see how my joints hold up.

The other day I was making some frame and panel assemblies and used the scraps to do destructive testing. I take the scraps and stress them until the point of failure. I am not using scientific equipment to measure the pounds per square inch, I just am getting a feel for how hard it is to break and I am examining the break.

By examining the break I am looking for the failure location. Is it the wood? Or is it the glue?

The waste piece in the photos happens to have a biscuit in it. I used to think biscuits added strength to the joint. I now believe that a good glue joint is stronger without the biscuit, but I use them to aid in the alignment of boards.

The panel I was cutting was 3/8" thick and I broke several pieces of waste to see if the results were consistent, which they were. You will see that the biscuit does not break, of course, and it adds some internal leverage to break the panel, but the glue joint itself did not fail. Ultimately, that is what I am looking for. Realistically,the panel will not suffer stress like this, but I want to test my glue joints.

Breaking the test piece.

Breaking the test piece.

Glue joint held, wood broke.

Glue joint held, wood broke. Examine the glue joint.

Examine the glue joint.

Through constant testing I have become secure in knowing that my glue joints are good. Testing allows me to gain confidence that the products and techniques are good. Pushing the waste pieces to the limit of failure gives me an opportunity to examine both.

A Video On Testing Glue Joints

Here is the video I made to demonstrate how I do destructive testing to check my glue joints. It has a lot of good information in it. I hope you enjoy!

Your friend in the shop, Todd A. Clippinger.

Share the Love~Share the Knowledge

Click Here For Direct Link To Episode